BT1

TYPE BT-1 WITH QUICK CHANGEOVER SYSTEM

The advantage of this multispindle drilling machine for heavy duty brake blocks is the quick change over time. A complete preinstalled set of drill units, fixed on a carrier system, can be changed in a few minutes.

A zero clamping system guarantied the accurate locating of the drill units. Drill fixtures as well loading and unloading derives are quick changeable too. No settings are necessary. The machine is designed for in line. Different drilling programs can be stored and easily selected.

The output is about 600 pieces per hour. This machine can run 24 hours 7 days a week without downtime!

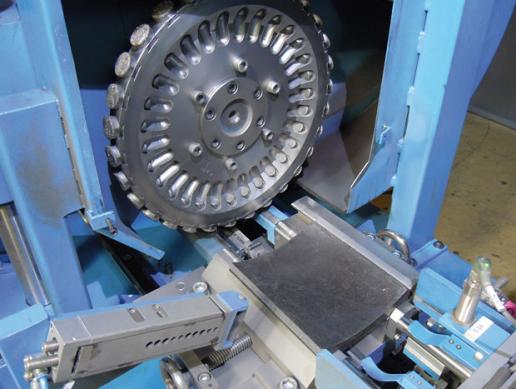

IRG

TYPE IRG-D FOR INSIDE RADIUS WITH DIAMOND WHEEL FOR HEAVY DUTY BRAKE BLOCKS

ERLMANN IRG-D is designed for the grinding of heavy duty drum break blocks after pressing and hardening process according to OEM-specification.

Grinding of up to 600 blocks per hour can be achieved.

The grinding wheel is mounted with 15 to 20 diamond coated grinding bodies, which are adjustable in high about 0,5 mm. These parts are easy to change. For each inside radius a corresponding basic grinding wheel is necessary. The grinding bodies are usable for the different basic units.

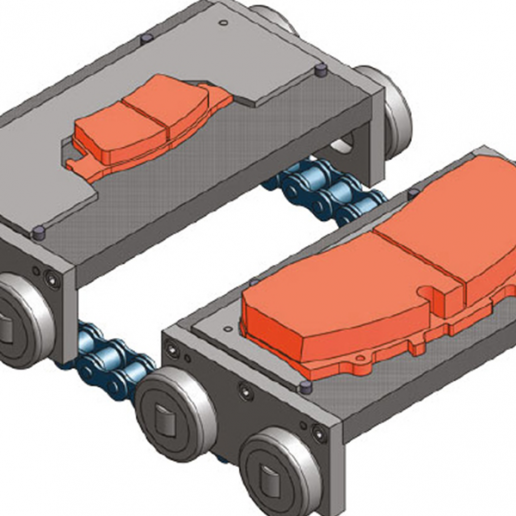

PGL

TYPE PGL: PAD GRINDING LINE

The PGL is a Universal Pad Grinding Line for disc brakes.

Modular constricted from one up to six or more workstations for machining of size, chamfer and notches in continuous mode.

Production rate: 1000 up to 2500 pieces per hour.

Grinding Thickness min. 9 mm

Grinding Thickness max. 30 mm

Pad Width min. 50 mm

Pad Width max. 270 mm

Pad Depth min. 30 mm

Pad Depth max. 110 mm

ORG

TYPE ORG-NC FOR OUTSIDE RADIUS FOR HEAVY DUTY BRAKE LININGS

The machine is designed to accurately grind the outside radius of brake blocks to true radii according to OEM-specification and based on ROWLAND design. Brake blocks can be parallel or taper curved. The machine is run by one operator who stacks blocks in a magazine. Ground blocks exit to short rails.

Grinding of up to 900 blocks per hour can be achieved. This machine has been developed to meet the demands of Brake Block Manufacturers to produce parallel and taper curved brake blocks, even in small batches.

This CNC grinding machine is designed to replace standard machines that use expensive and inflexible tooling, reduce changeover time and offers many advantages over traditional machines, including:

Ability to grind taper and parallel blocks from a simple low cost cylindrical fixture drum made to the inside radius of the block.

BU-NC

TYPE BU-NC FOR HEAVY DUTY BRAKE LININGS

The forementioned machine has been developed especially for drilling of drum brake linings for commercial vehicles. More than 200 machines have been built and sold to customers throughout the world.

The advantage of this machine is the big versatility. It works numeric controlled and covers nearly the total range of the worldwide existing drill patterns. That means, the machine allows drilling of linings or blocks

- from 135 mm up to 250 mm inside radius

- from 25 mm up to 260 mm width

- with up to 12 holes per row

- with up to 8 rows

The machine is programmed by a PLC SIEMENS S7. All functions can be dialled and handled on a touch panel, also the programming and saving of the row position and the pattern of the brake lining type which should be drilled.