The windshield wiper is a device we always see but never notice. It serves dutifully in trillion of vehicles around the world, cleaning windshields from rain and dirt and keeping passengers safe and dry. In this fourth and last article in a series about windscreen wipers we take a look at the different kinds of wiper blade systems used on modern passenger cars. In the first part we looked at the early inventors of windshield wipers, on the second part we looked at inventions that further improved the wiper’s workings, and in the third part we checked out modern windshield wiper inventions.

Car manufacturers, in conjunction with windshield wiper makers, have long been looking for the perfect wiper blade mechanism. Simply said, the perfect mechanism cleans most of the windshield’s surface. That, in the end, is the goal of a windshield wiper. But car makers have to look at other factors too. The wiper blade and wiper blade mechanism have to be affordable to manufacture, easy to maintain, and cheap to replace. Furthermore, there are limits to energy consumption and size of a wiper. A wiper with too much energy consumption would drain the battery. An oversized wiper would harm a car’s aerodynamics and thus increase fuel consumption. In short; finding the perfect wiper mechanism is about finding a balance between a properly clean and dry window, cost, and the all-round functionality of a motor vehicle. What are the most common solutions?

Basic single blade wiper systems

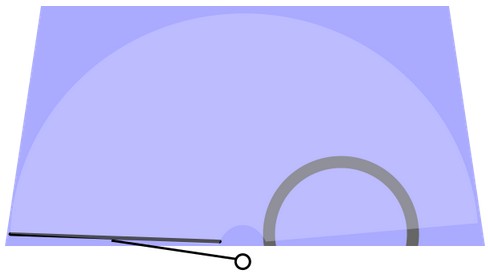

A single wiper system has obvious advantages: good for aerodynamics and bad for complexity, which is a good thing. A single wiper has a single motor installed in the middle. The main disadvantage is the relatively small wiper area.

This is a basic single blade wiper system, with the wiper blade wiping a single arc over the windscreen. Large portions of the windscreen are not wiped: top left, top right, bottom-left, and middle. This solution is therefore not ideal. It has mainly been used in economy cars, with the purpose of keeping costs down. Well-known examples are the Citroen AX, Fiat Panda, Seat Ibiza, and the Volkswagen Scirocco.

A single blade wiper system on the Citroen AX.

Complex single blade wiper systems

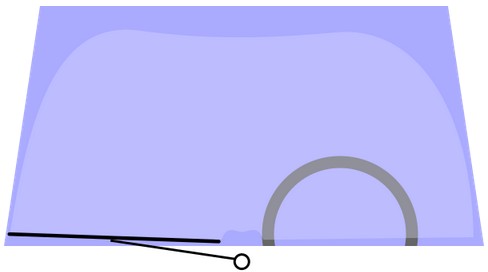

Still, considering the advantages of single blade wiper systems, manufacturers have been trying to add improvements to enlarge the wiper area. The most common way to do so it by installing an extendable and retractable wiper blade. While wiping, the top end of the blade would extend and retract where needed to make the wiper area as large as possible. At first glance, this seemed an ideal solution. But it wasn’t for an obvious reason: the wiper added complexity, was more expensive to produce and to replace, and needed for maintenance. Many car makers experimented with complex single blade wiper systems. Some example are the Audi A2, the Mercedes-Benz 190 & E-Class, and the Subaru XT.

The best known proponent of complex single wiper blade system is Mercedes-Benz. They called it the ‘Monoblade Wiper’. The first car that got the system was the 1982 Mercedes-Benz 190. The car in the video is a 1984 Mercedes-Benz E-Class.

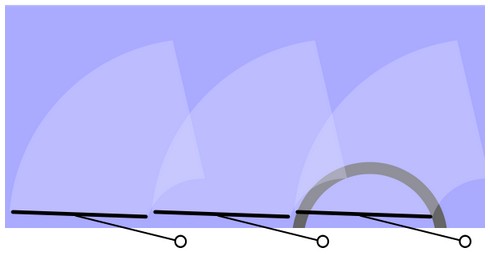

Parallel dual windscreen wiper blade systems

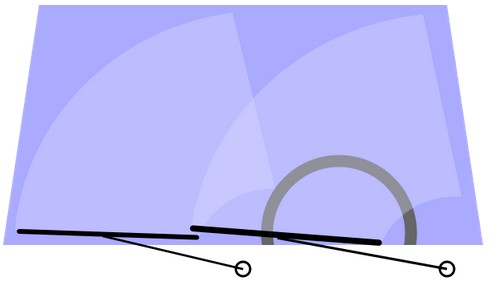

The parallel dual windscreen wiper blade is the most common wiper blade mechanism on passenger cars. And like with almost all most-commons, it is a compromise. The two wipers are relatively small, thereby minimizing drag. They wipe a large part of the windshield, and, even more important, the wipe the areas that are most likely to be in a driver’s sight. Finally, due to their parallel modus oprandi, the system isn’t overly complex. In a parallel system, the wipers wipe in the same direction; seen from the front: from bottom to left. And because this is the most common system, production is cheap and replacements are affordable.

A parallel dual windscreen wiper blade system in action in a 2010 Volkswagen Jetta.

Opposite dual windscreen wiper blade systems

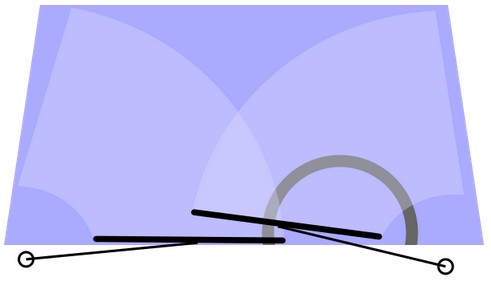

Opposite dual windscreen wiper systems may look similar to parallel systems but in reality they are quite different. First, the location of the wiper motors differs. With parallel systems, the motors are in the middle and on the right. With opposite systems, the motors are on the far sides. Even more significant is the wipe direction; with an opposite systems, the wipers move in an opposite directions relative to each other. Each wiper wipes one side of the windshield. The positive is a slightly larger wiper area. But the system’s dynamics are more complex and costs are therefore higher. This system is usually fitted on cars where the windshield design doesn’t allow for a proper operation of a parallel systems, for example when a windshield is rounded or very large. Some examples of passenger cars with opposite dual windscreen wiper systems are the Citroen C6, Ford S-Max, Peugeot 307 and 308, and the Smart Fortwo.

An opposite dual windscreen wiper systems in action in a Peugeot 307.

Triple parallel windscreen wiper blade systems

The final system we discuss today is a somewhat exotic bird: triple parallel windshield wiper blade systems. These systems use three wiper blades and three motors. The blades wipe in a parallel direction, seen from the front from bottom to the right. The advantage is a large wiper area. The disadvantage is the complexity and the extra costs. Each extra wiper is, well, and extra wiper. Any windshield could be as clean and dry as a mirror of only an automaker would fit 10 wipers, right? Anyway. Tripe wiper systems are extremely rare on passenger cars. In the 1960’s they were fitted on British sports cars that were exported to the US, where a law required a certain wiper coverage for imported cars. The most famous triple wiper cars were the Austin Healey Sprite, Jaguar E-Type, and the MGB.

In modern times, the best known passenger car with a triple parallel windscreen wiper blade system is the Toyota FJ Cruiser, a retro-styled 4×4. Toyota fitted the triple wiper system for added coolness, not for any specific technical reason. And it worked, as the video shows. Yes, wipers can be cool!

And those were the main kinds of wiper blade systems used on modern passenger cars. That means we are at the end of this series. But there may be a 5th part in the future, as several automakers are experimenting with a entirely new generation of windshield wiper systems. Tesla, for example, is developing a wiper system that uses lasers instead of wiper blades. If that works out, the story of the windshield wiper will suddenly go into an entirely new direction indeed.